Approximately 40 years ago, CONOU – Italy’s National Consortium of Waste Oils – became the first to inaugurate an applied extended producer responsibility scheme to collect and regenerate, on behalf of lubricant oil producers, their clients’ end-of-life oils. In a sector where the circular economy has always been implemented, Italy’s consortium model has achieved extraordinary results in recent years, so much so that it has become a veritable case study for other European countries.

The ingredients for a virtuous EPR system

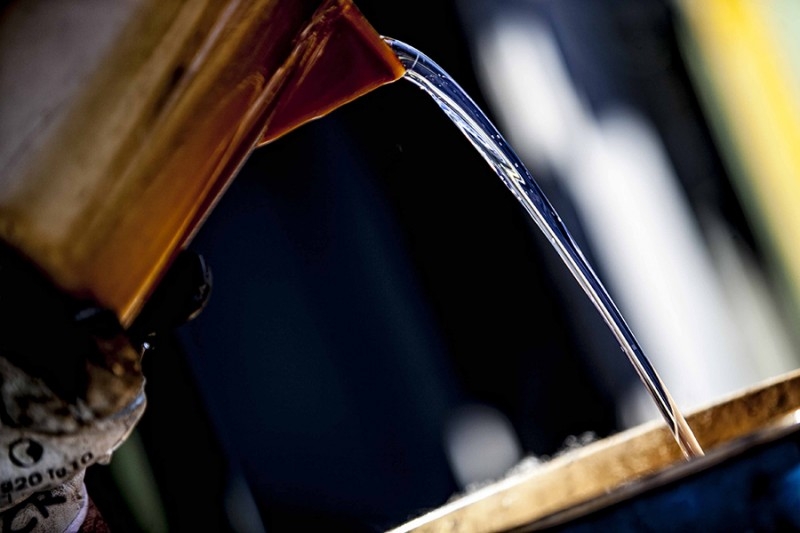

Reading the findings of the latest sustainability report, it seems very complex to find new challenges and targets that could improve CONOU’s results. From the 181,000 tonnes of used oil collected in 2022 (almost the totality of what could be collected), the Consortium has produced 118,000 tonnes of new lubricating bases and over 38,000 tonnes of bitumens and gas oils, achieving a 98% regeneration rate.

The benefits that follow from this circular cycle are not only environmental, like the 64,000 tonnes of CO2 equivalent emissions avoided, 29% of water saved, the 77% reduction of land use, or the 91% reduction in the incidence of diseases linked to particulate emissions. The circularity of mineral oils, in 2022, also brought positive outcomes in social and economic terms, with savings worth 130 million euros thanks to the avoidance of crude oil imports and the employment of 1,216 people throughout the supply chain. All of this is thanks to the work of a capillary network of collectors that gather used oil from some 103,000 workshop and factory sites, distributed throughout Italy, and of the two regeneration companies that provide their vital contribution to closing the circle.

“I believe that the not-for-profit consortium model is decisive,” CONOU’s president Riccardo Piunti tells Renewable Matter, “because it provides guarantees to all stakeholders in the supply chain: those who sell lubricant oils and, through the fees that they pay, provide the economic resources the Consortium needs to operate, as well as those who collect the spent oils wherever necessary and offer up their storage facilities. Finally, also to those who close the circle within this system by transforming used oil into a new usable product.” According to Piunti, the Consortium functions to balance, control, and guarantee the priority of regeneration without having any specific economic interest among the stakeholders: “we are doing a lot of work on the participation in the supply chain of all our members; the Consortium must be able to keep track, dialogue, and listen to everyone’s needs.”

CONOU’s “drivers” leading the collection effort

In 2022, CONOU achieved a regeneration rate close to 100% of all oil it collected. This is exceptional, especially considering that at the EU level, only an average of 61% of used oil is regenerated. Thus, a considerable portion of it is burned, massively devaluing the quality of this waste/resource.

Of the 181,000 tonnes collected in 2022, 86,000 (47% of the total) came from so-called micro-collection. This term relates to the small amounts of used oil whose collection is not always profitable but is nevertheless carried out (for free) thanks to the contractual systems that link collection licensees to CONOU, thus avoiding dispersal into land or water, in line with the primary goal of environmental protection.

President Riccardo Piunti often notes the key role of collection drivers, who know all about the small or large workshops from which they collect used oils. “The collection points can sometimes be in remote places that are difficult to access or where oil collection using the appropriate equipment is a complex operation. Our drivers build a personal relationship with the “village mechanic” so as to create the conditions for efficient and effective collection.”

Franco Venanzi, the president of ANCO (the National Association of Consortia Licensees), whose company goes and collects, for free, all the oil that it is possible to collect, knows the importance of establishing those relationships. It does not matter whether it is 50 kilos of oil from a small workshop or a tonne of oil from a factory, collectors can go anywhere and always bring with them the expertise needed to assess the quality of the oil being collected. In fact, to be regenerated, the used oil must meet certain quality standards that are then confirmed through laboratory analysis. “The problem with mineral oil is that it is black and liquid,” says Venanzi. “There is a risk that it is mixed with water, thinners, solvents, paints, or other impurities. Its colour makes it impossible to assess whether such impurities are present. In rare cases, when the oil does not meet a certain level in terms of quality, the workshops must pay an environmental fee that enables its disposal.” This system works because it incentivises both small and large businesses to store their oil correctly, without costs for the waste producers but actively contributing to virtuous circularity.”

This article is also available in Italian / Questo articolo è disponibile anche in italiano

Image: CONOU

© all rights reserved